News

2011-2021. Our first ten years

21 May 2021

Pont-Saint-Martin, 21 May 2021 - Podium was founded on May 21, 2011 and celebrates today its first 10 years of operations.

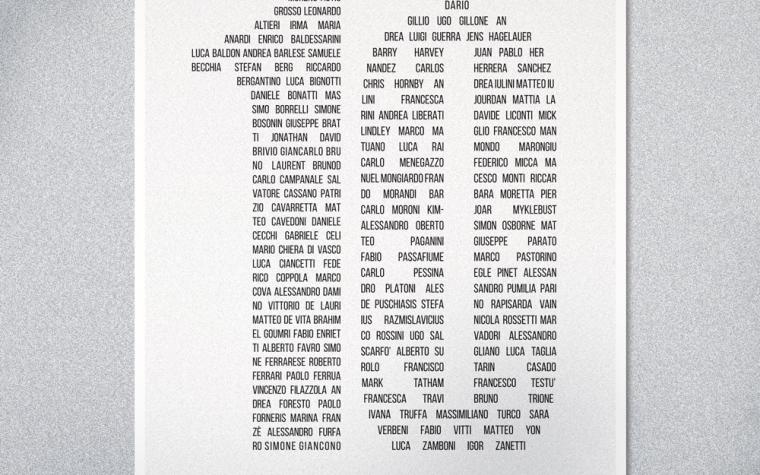

Podium CEO Francesco Monti: “This important anniversary is marked by the latest exceptional technical and business results such as the delivery of a unique and innovative battery system to Hitachi Rail, the debut of the new Glickenhaus 004C Evo at Nürburgring and seven FIA world land speed records just broken by the research prototype Blizz Primatist designed and built by Podium Advanced Technologies. We celebrate this important milestone acknowledging the contribution that our employees and all the people who worked with Podium over these first 10 years have brought about.”

“We are looking forward to participating at the FIA World Endurance Championship with the Glickenhaus 007 LMH - Le Mans Hypercar, designed and built by Podium, which has successfully completed a series of performance test in the last weeks at the circuits of Vallelunga and Monza. This is one of the major projects for us in this sector, a championship that represents the most important class after Formula 1”, CEO Francesco Monti underlines.

Recently, Financial Times picks Podium for the fourth year in a row among Europe’s 1000 fastest growing companies “This makes everybody here in Podium very proud and it demonstrates that our founding values, business ethics and customer focus are delivering consistent results”, Podium CEO Francesco Monti underlines.