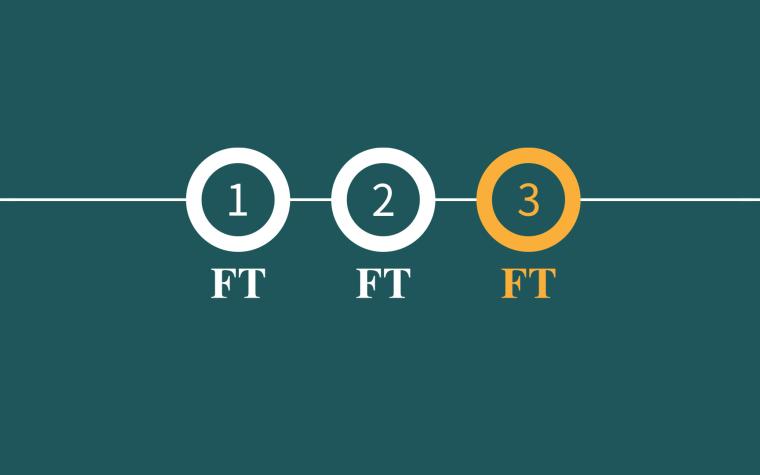

For the third consecutive year the Financial Times picks Podium Advanced Technologies among Europe’s 1000 fastest growing companies

London, 13 March 2020 - The Financial Times has published today the full FT1000 2020 ranking, recording the 1.000 companies in Europe that have achieved the highest growth in revenues between 2015 and 2018. The FT 1000, compiled with Statista, a research company, lists the European companies that achieved the highest compound annual growth rate in revenue between 2015 and 2018. Competition is even tougher at the top this year, with companies requiring a minimum growth rate of 38.4 per cent to make the list, compared with 37.7 per cent last year. Only 90 companies have been able – as Podium Advanced Technologies has – to make the ranking in three consecutive years. FT1000 this year places Podium Advanced Technologies in the top 4% of the Automotive sector, in the top 25% of Italian companies and in the top 37% overall, thanks to an absolute revenue growth of + 468%, or a CAGR of + 78%, over the three years period. The key drivers of revenues growth in 2018 have been the launch of the Automobili Amos Delta Futurista program, a full racing season run at the Nürburgring and COTA with Scuderia Cameron Glickenhaus, and the inception of the new high capacity batteries and electric powertrains testing activity. A full special report shall be published on Financial Times next March 23. Please see the full FT1000 ranking atthis link