News

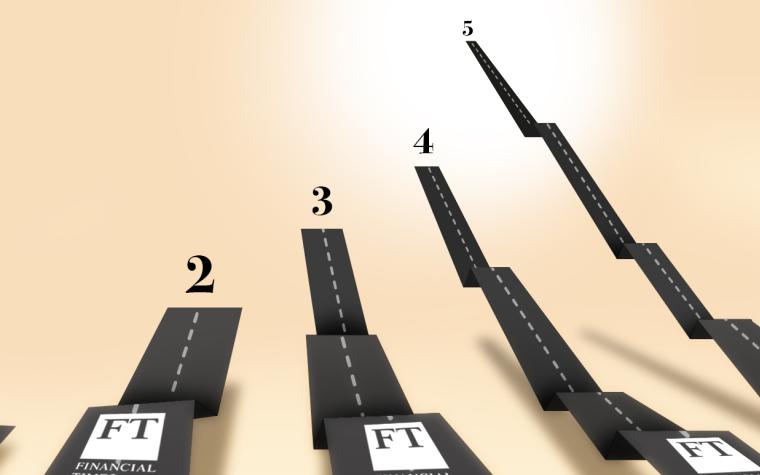

Revenue in 2021 surpassed 30 million Euro while the Financial Times picks Podium for the fifth year in a row among Europe’s 1000 fastest growing companies

02 Mar 2022

London, 2 March 2022 - A rare case in the history of this acknowledgement, plus a record revenue year

Revenues for 2021 surpassed 30 Million EUR while for the fifth year in a row the Financial Times picks Podium Advanced Technologies among Europe’s 1,000 fastest growing companies - a rare case in the history of this acknowledgement - thanks to an absolute revenue growth of + 745% and a remarkable 103.7% CAGR in revenues over the period, from 2.1 million Euro in 2017 to 18 million Euro in 2020.

Podium enters the top 20% of the global report and reaches the 3th position overall in Europe considering all the companies operating in the automobiles sector.

Podium is one of few companies (6 in total out of 1,000) able to make the ranking in five consecutive years from 2017 to 2021 all over Europe. An astonishing result due to a continuous focus on huge investments, aimed also to the construction of a new research center centered on the design, development and assembly of battery systems for special applications, expected to open in the current year.

Podium CEO Francesco Monti underlines: “Our growth results from continuous investments in our people and from strong and long-lasting relationship with our customers, key suppliers and partners that enable us delivering successfully results in all our projects and ventures. From the moment it started its operations in 2011, Podium Advanced Technologies has been continuously growing thanks to the relentless engineering activities of all our employees and the trust that an increasing number of important new and old customers have placed on us.”

Last year has been dotted by important milestones such as the development of bespoke battery systems for special applications in several industries, the conquest of seven FIA world land speed records with the research prototype Blizz Primatist and the participation in the FIA World Endurance Championship with the Glickenhaus 007 LMH, which scored 4th and 5th overall at the legendary 24 Hours of Le Mans. “This has been one of the major projects for us in this sector, a championship that represents the most important class after Formula 1”, CEO Francesco Monti underlines.

The FT 1000: Europe’s Fastest Growing Companies is a list of the top 1000 companies in Europe that have achieved the highest growth in revenues between 2017 and 2020. Please visit the FT1000 rankinghere. The full report featuring case studies and analysis will be published on March 21.